Hi Naseem,

Getting STL model data directly from the manufacturer can be quite difficult.

In many cases, you need a strong personal connection — for example, the name of a well-known professor or orthopedic surgeon who has a close relationship with the company — in order to even initiate the conversation. This is because the implant geometry itself is considered intellectual property, and manufacturers must trust that the data will be used strictly for research purposes.

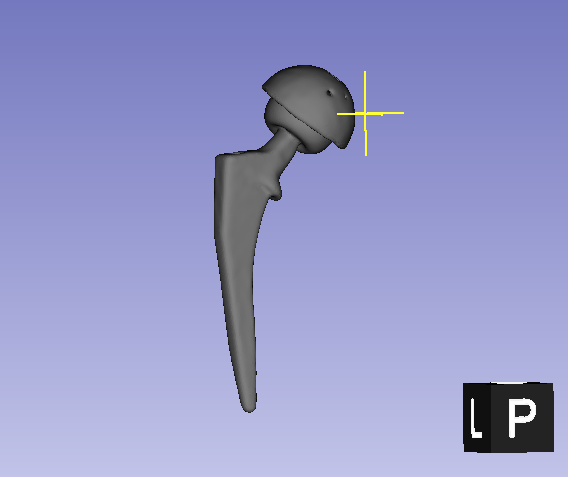

If you’re only looking for approximate models, you can try searching for terms like “STL THA free.” You’ll find several websites offering STL files. However, please note that these are merely look-alike models. They might appear realistic, especially with surface textures applied, but in FEA, visual realism is less important than accurate contact conditions.

If you’re familiar with CAD software, you might be able to reconstruct a 3D model based on 2D templates. These are sometimes provided to surgeons by manufacturers and printed on transparent sheets as part of standard surgical planning materials. But again, such reconstructions are also only approximate.

One thing to keep in mind is that THA implant sizes often do not follow a simple scale-up or scale-down pattern. For example, smaller sizes may have steeper or shallower taper angles. So, the more effort you put into modeling, the better your reconstruction might be — but it will still be an approximation.

Ultimately, which of these approaches you take depends on what exactly you want to validate or explore through your FEA.

By the way, while some manufacturers have product search pages on their websites where you can look up implant model numbers, accessing detailed templates — even just 2D ones — is usually quite difficult due to intellectual property restrictions.

Even for licensed surgeons, obtaining such data typically requires formal requests and trust-based relationships. For non-clinicians, especially graduate students, it can be even more challenging.

So unfortunately, these resources are not generally available to the public.

It seems that you’re facing exactly the same challenges I encountered a few years ago — and you’re now trying to go even further beyond them.

I’m sure there will be many difficulties along the way, but I truly hope your research goes well and leads to meaningful results.

Best of luck with your work!